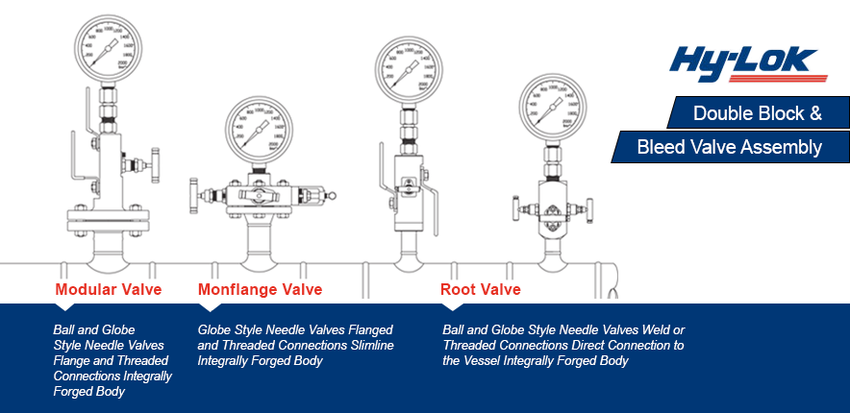

Double Block and Bleed Valves

At Hy-Lok, we create value for our clients by engineering high quality double block bleed valves customized to match individual process requirements.

Our compact, integrated designs and accurate, rugged construction provide a high reliability solution for complex multiple instrument valve systems. Able to tolerate temperatures from -70.6°F to +1,002°F, and pressures to 10,000 psig, our products reduce overall fluid system weight and height, provide fewer leak paths and eliminate the damaging effects of system vibration.

Our unique design approach achieves the highest level of seal integrity and optimal process compatibility. We create flexible configurations with a wide variety of end connections, body types, and valve technologies for critical piping applications including instrument isolation; pressure, level and flow measurement; instrument drain; chemical injection; and sampling.Constructed primarily from 316 stainless steel, a variety of material options for ball seat, trim, stem, and end connector o-rings are available to accommodate specific process conditions.

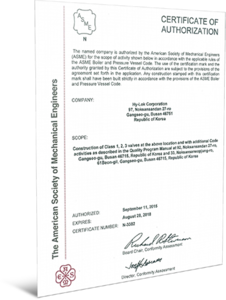

We manufacture our valves under the strict controls of our ISO 9001 and ASME certified quality assurance program to ensure process integrity. In addition to sourcing only premium quality materials, our Heat Code Traceability system provides technical documentation verifying that raw materials meet all code requirements. We pressure test each valve to withstand client-specific plant conditions and repeatedly measure products for dimensional accuracy at all critical points in the production cycle.

For more information about our custom valve manufacturing capabilities, please review the table below.

Highlights of Hy-Lok's Double Block & Bleed Valves

| Product Name | Double Block and Bleed Valve |

|---|---|

| Function | Provide compact installation for gauge or transmitter instruments |

| Alternative to multivalve systems | |

| Valve Types | Modular Valve |

| Monoflange Valve | |

| Root Valve | |

| Options | BAll Seta Material |

| Trim Material | |

| Stem and End Connector O-Ring | |

| Advantages | More compact design |

| Reduced weight/height | |

| Reduced leakage points | |

| Reduced effect of system vibration | |

| Supporting brackets are not required | |

| Reduced bending moment acting on the vessel | |

| Reduced installation cost | |

| Reduced Gaskets and Bolting | |

| Materials | 316 Stainless Steel |

| Monel | |

| Duplex | |

| Super Duplex | |

| Hastelloy | |

| Inconel | |

| Testing | Hardnesss testing |

| Fire testing | |

| Dimensional Inspection | |

| Hydrostatic testing | |

| Full Pressure testing | |

| Hydrostatic Seat Test | |

| Pneumatic Test | |

| Temperature | Min: -70.6 F |

| Max: 1022 F | |

| Pressure | Max: 10,000 psig |

| Size | Varies |

| Quality | Quality Assurance |

| Material | |

| Identification | |

| Production Volume | Low Volume |

| Short Runs | |

| Prototyping |

Additional Information

| Industry Focus | Architectural |

| Chemical | |

| Electronic | |

| Power Generation | |

| Labortory | |

| Oil/Gas | |

| Petro-Chemical | |

| Power | |

| Applications | Double Block and Bleed Instrument Isolation |

| Gauge Isolation | |

| Instrument Drain | |

| Chemical Injection Connection | |

| Sample Connections | |

| Chemical Seal Instrument Isolation | |

| Piping/instrument Interface | |

| Direct Mounting of Instruments | |

| Remote mounting of instruments | |

| Industry Standards | ANSI - American National Standards Institute |

| ASME - American Society of Mechanical Engineers | |

| API - American Petroleum Institute | |

| ISO - International Organization for Standardization | |

| File Formats | AutoCAD (DWG,DWZ) |

| DXF - Drawing Interchange Format, or Drawing Exchange Format | |

| IGES - Initial Graphics Exchange Specification, ANSI file format | |

| JPG or JEPG - Joint Photographic Experts Group | |

| PDF - Portable Document Format | |

| Pro-E or Pro/Engineer (DRW,PRT,XPR) | |

| SolidWorks (SLDPRT,SLDDRW,SLDDRT) | |

| STEP - Standard for the Exchange of Product Model Data |